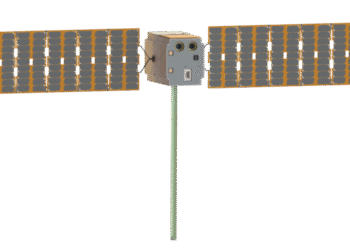

NASA has developed a new metal alloy suitable for 3D printing, which is expected to revolutionize applications in environments with high temperatures. This breakthrough material can significantly withstand harsh conditions commonly encountered in space exploration missions.

Unveiling the Alloy

Named Alloy GRX-810, this development marks a substantial improvement in materials used for high-temperature applications. The new alloy is not only robust but also lightweight, which is essential for efficient spacecraft design and construction.

Significance of the Development

The alloy’s properties support the creation of parts that can endure the extreme conditions of space, including temperature fluctuations and radiation exposure. These parts are expected to last longer and perform better, reducing the need for replacements and maintenance.

- Increased durability and performance in adverse environments.

- Potential to reduce costs associated with part replacements and maintenance.

- Enables more complex and efficient designs.

Applications

This innovation is not limited to space exploration. The potential applications of Alloy GRX-810 can extend to industries such as aerospace, defense, and automotive, where high-temperature resistance materials are in demand.

- Aerospace: Enhancing aircraft engine performance and safety.

- Defense: Building more resilient and reliable military equipment.

- Automotive: Improving engine components’ longevity and function.

For more detailed information, please visit the NASA Technology Transfer page about the Printable Metal Alloy.