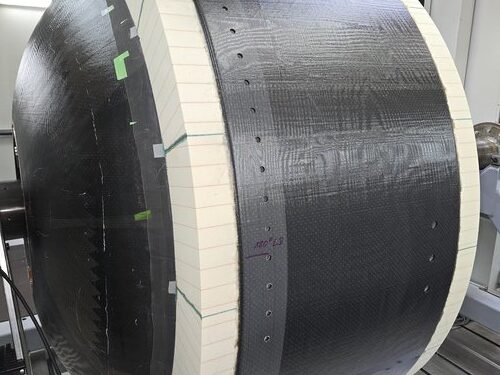

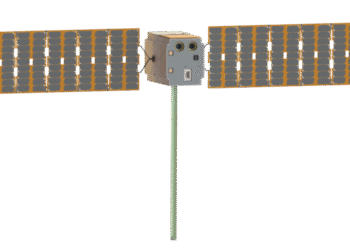

The European Space Agency’s Phoebus program is advancing a full-scale, carbon-fiber reinforced plastic liquid hydrogen tank designed for potential use on the Ariane 6 upper stage. Following successful small-scale demonstrations, a 2,600-liter, 2-meter-diameter tank is nearing completion, with hydrogen testing targeted from April 2026 at ArianeGroup’s site in Trauen, Germany. The effort is part of ESA’s Future Launchers Preparatory Programme (FLPP) and aims to validate weight-saving composite cryogenic tanks that could remove several tonnes from an upper stage.

What’s new

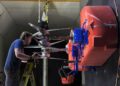

MT Aerospace in Augsburg, Germany, completed initial manufacturing steps for the inner pressure vessel in September 2025, with production expected to conclude in December 2025. ArianeGroup is preparing the dedicated test facility and will lead the tank qualification campaign, which will progressively load the tank to the onset of cracking without reaching catastrophic failure. The facility passed a preliminary design review in June 2025, and a critical design review is planned by year-end to enable civil works.

Why it’s hard

Liquid hydrogen must be stored at about −253 °C, just above absolute zero. Hydrogen’s small molecular size and extreme cryogenic conditions drive permeation and microcracking risks in composite structures. The Phoebus team has developed tailored materials, processes and measurement approaches, including instrumentation capable of capturing minute leak rates and strain behavior at cryogenic temperatures. Safety remains central, as hydrogen is highly flammable even when cryogenic.

What’s already been proven

Earlier 60-liter composite “bottle” tanks demonstrated that carbon-fiber reinforced plastic can contain liquid hydrogen without measurable leakage. Those results underpin the scale-up to the 2-meter-class tank now entering final production.

Test campaign and instrumentation

The Trauen test site work began in February 2025. Multiple runs are planned to emulate prelaunch and ascent environments and to map where and how initial cracks could form. The tank will be equipped with sensors to capture pressure, temperature and strain, enabling detailed correlation between loads and cryogenic performance after each run.

Implications for Ariane 6 and beyond

If validated, composite cryogenic tanks could deliver substantial mass savings for upper stages, improving payload capability or performance margins. The technology also carries potential benefits for industrial hydrogen storage and ground systems. As part of ESA FLPP, Phoebus reduces risk for future implementations by maturing materials, manufacturing, and test capabilities ahead of any flight adoption decisions.

Key milestones

- February 2025: Test site activities kicked off at Trauen (ArianeGroup).

- June 2025: Test facility passed Preliminary Design Review.

- September 2025: Inner pressure vessel manufacturing steps completed at MT Aerospace.

- December 2025: Tank production expected to finish.

- Late 2025: Critical Design Review planned; start of civil works at the site.

- April 2026: Hydrogen test campaign planned to begin in Trauen, Germany.

Source: ESA – Phoebus: keeping the smallest molecule in the Universe contained