NASA’s Engineering and Safety Center (NESC) has identified bake-out of silicone-based thermal control coatings as a critical step to maintain the optical stability of spacecraft white paint in low Earth orbit. A review of flight data, ground tests, and historical literature indicates that volatile compounds within these coatings—not the silicone binder or zinc-oxide (ZnO) scatterers—are the primary drivers of ultraviolet (UV)–induced darkening. The findings help explain long-standing discrepancies between lab and on-orbit performance and point to practical processing steps that can extend coating life.

Why this matters

Spacecraft thermal balance hinges on two properties: absorptivity (how much solar energy is absorbed) and emissivity (how efficiently heat is radiated). White thermal control coatings keep vehicles within design temperature ranges, but their optical properties can degrade under solar UV, especially in LEO. Variability in the UV stability of ZnO–silicone paints has complicated material selection and lifetime prediction across missions.

What the NESC review found

- Ground-test variability traced to volatiles and UV spectrum: Identical ZnO–silicone paints tested at two facilities degraded at rates differing by more than a factor of six. The key differences were whether samples were prebaked (removing volatiles) and the UV irradiance spectra used, both of which strongly influenced outcomes.

- Prebake greatly reduces UV darkening: Historical data show that prebaked samples experience far smaller increases in absorptivity. For example, S-31 paint changed by about 0.02 after 1,780 equivalent solar hours (ESH) without prebake, versus ~0.006 with a 260°C, 1-hour prebake. For S-33, adding a second prebake at 260°C reduced the change from ~0.02 to ~0.011 after 4,170 ESH, comparable to high-performing silicate-based systems.

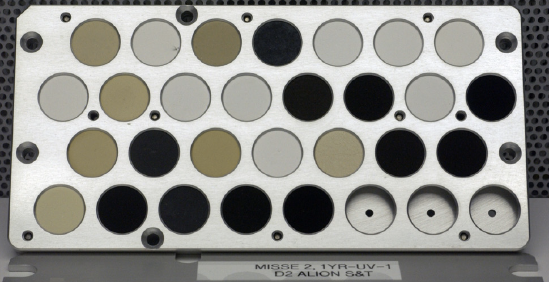

- On-orbit observations align with prebake benefits: MISSE experiments reported large reductions in UV degradation for prebaked samples. In one case, a prebaked ZnO–silicone specimen showed a net absorptivity change of ~0.011, compared with ~0.27 for a similar unbaked sample, with positional effects noted. Flight data from spacecraft using the same paint show minimal degradation over long periods, likely because the coating over insulating layers heats in sunlight, providing a near-continuous in-flight bake-out that removes residual and UV-generated volatiles.

- Root cause clarified: Comparative outgassing data and performance trends support the conclusion that UV interactions with paint volatiles dominate discoloration, rather than damage to the silicone binder or ZnO particles.

Implications for spacecraft programs

- Process control: Incorporate defined prebake steps for ZnO–silicone coatings to reduce retained volatiles before exposure to UV.

- Test representativeness: Align facility UV spectra with solar conditions and standardize prebake protocols to improve correlation between ground tests and flight.

- Configuration effects: Consider substrate and thermal stack-up. Coatings over insulating layers may self-bake in orbit, while metal-backed coupons may not replicate flight heating.

- Modeling and life prediction: Update degradation models to include volatile content, outgassing kinetics, and in-flight thermal histories.

- Material trade studies: Reassess ZnO–silicone paints in light of controlled bake-out, given their mechanical advantages over silicate binders.

What’s next

NESC coupon testing initiated in FY25 and completing in FY26 aims to quantify UV stability under controlled prebake and spectral conditions, improving predictive confidence for LEO missions. Results could inform updates to qualification standards, acceptance test plans, and maintenance of thermal optical property budgets across long-duration operations.

Read the NASA summary here: Baking Out Volatiles Key to Stable Spacecraft White Paint, NASA Review Says.