A NASA-backed engineering effort at the University of Iowa has restored domestic production of high-fidelity fluxgate cores and introduced a miniaturized Space Weather Iowa Magnetometer (SWIM) that matches or exceeds the performance of larger predecessors. The advancement targets a longstanding supply gap in precision magnetometer components and aims to support future heliophysics and operational space weather missions.

Why it matters

Fluxgate magnetometers are foundational for measuring space and planetary magnetic fields, informing models of geomagnetic storms that can disrupt power grids, communications and satellite operations. For years, high-end ferromagnetic cores relied on legacy processes no longer available to civilian programs. By re-establishing a modern, repeatable process, the team reduces supply-chain risk and opens the door to compact, low-power instruments suited to small satellites, deployable booms and sounding rockets.

How the new cores are made

The University of Iowa process starts with base metal powders that are melted into custom alloys, rolled into thin foils, formed into fluxgate core geometries, and heat treated to optimize magnetic properties. The cores are then integrated with in-house designed sensors and electronics, enabling rapid iteration on sensor geometry. The manufacturing line is now well documented, and roughly 90% of produced cores achieve a noise floor comparable to or better than legacy parts, supporting reliable scaling and repeat production.

What’s new in SWIM

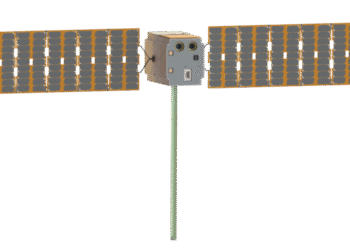

- Reduced sensor size and mass: SWIM is about 30% smaller than the MAGIC Tesseract sensor used on NASA’s TRACERS mission. The new design uses three smaller cores of the same geometry instead of six, and can be built with a lightweight carbon-composite cover (or no cover) to reach approximately 110 g, easing boom accommodation on small spacecraft.

- Lower power consumption: Improved metallurgy and fewer cores cut SWIM’s sensor power draw by roughly a factor of two versus the MAGIC sensor. Lower heat dissipation at the boom reduces thermal gradients that can affect pointing stability.

- Updated electronics topology: SWIM replaces traditional analog demodulation with digital demodulation and uses temperature-compensated, digital pulse-width-modulated magnetic feedback. This architecture enables the use of components with higher radiation tolerance, supporting longer-duration missions and harsher environments.

Performance and integration

Prototype SWIM racetrack cores demonstrate low magnetic noise, with example measurements of under 5 pT/√Hz at 1 Hz. The sensor maintains equal or better figures of merit compared to the MAGIC instrument, including mass, power, volume, magnetic noise and offset. As with most precision magnetometers, SWIM is designed for boom deployment to minimize spacecraft-generated magnetic interference. The documented manufacturing flow and yield indicate readiness to produce cores for the SWIM payload and follow-on missions.

Flight opportunities and next steps

The first flight opportunity for the SWIM fluxgate is the University of Oslo’s ICI-5bis sounding rocket, scheduled for winter 2025/2026 from the Andøya Space Sub-Orbital range in Norway. Additional flights, including the Observing Cusp High-altitude Reconnection and Electrodynamics (OCHRE) mission, are planned. The work is sponsored by NASA’s Heliophysics Strategic Technology Office. For more details, see the NASA overview: Making High Fidelity Fluxgate Cores for Space Science and Space Weather Missions.